BPY G Series

Stainless Steel Seamless Sampling Cylinder

ASTM D1265

Precision, Safety, and Versatility for Your Sampling Needs

Product Overview

The BPY G series stainless steel Seamless Sampling Cylinder ASTM D1265 are designed to meet the highest standards of quality and safety for the collection, transportation, and storage of liquefied petroleum gas (LPG), liquefied natural gas (LNG), hydrogen sulfide (H₂S), sulfur-containing sewage, hydrocarbons, and other toxic or harmful substances, as well as nitrogen (N₂), oxygen (O₂), carbon dioxide (CO₂), and other gaseous or liquid samples.

Our BPY G Seamless Sampling Cylinder ASTM D1265 are meticulously crafted to comply with international standards such as TSG R0004-2009, GB/T 5099-2017, SH/T0233, ISO 4257, and ASTM D1265, ensuring reliability and performance in various industrial applications.

BPY G Sampling Cylinder ASTM D1265

BPY G Sampling Cylinder ASTM D1265

BPY G Sampling Cylinder ASTM D1265

LPG Sampling Cylinder ASTM D1265

Liquefied Petroleum Gas Sampling Cylinder

LPG Sampling Cylinder ASTM D1265

Liquefied Petroleum Gas Sampling Cylinder

LPG Sampling Cylinder ASTM D1265

Liquefied Petroleum Gas Sampling Cylinder

Key Features

- Single Spinning Forming Technology: Our BPY G series Seamless Sampling Cylinder ASTM D1265 are made from 316L stainless steel using a single spinning forming process, eliminating the need for welding. This ensures uniform wall thickness and superior corrosion and high-temperature resistance.

- Smooth Inner Surface: The inner surface of the BPY G Seamless Sampling Cylinder ASTM D1265 is passivated by pickling, resulting in a smooth interior that is easy to clean and minimizes the risk of sample contamination.

- Over-Pressure Protection: Each BPY G Seamless Sampling Cylinder ASTM D1265 is equipped with a safety relief device to prevent over-pressurization, providing an additional layer of safety during sampling operations.

- Customizable Accessories: We offer a wide range of accessories, including PTFE coatings, metal hoses, pressure gauges, quick connectors, reserved volume tubes, and more, to meet the specific needs of different sampling environments and media.

- Versatile Applications: Our BPY G Seamless Sampling Cylinder ASTM D1265 are suitable for use in storage tanks, tank cars, tower equipment, production pipelines, and other conventional devices, making BPY G Seamless Sampling Cylinder ASTM D1265 ideal for the petrochemical, pharmaceutical, educational, and food inspection industries.

Main Technical Parameters

| No. | Tech Indicator | Description |

| 1 | Working Pressure | BPY series: 4Mpa; |

| BPY - G series: 20Mpa | ||

| 2 | Design Pressure | BPY series: 6Mpa; |

| BPY - G series: 30Mpa | ||

| 3 | Operating Temperature | -60℃ ~ +80℃ |

| 4 | Applicable Medium | Non-corrosive Liquid and Gaseous Medium for 316L Stainless Steel Within The Specified Range of Temperature and Pressure. |

| 5 | Material | 316L Stainless Steel |

| 6 | Valve | M14*1.5(8mm jacket) / 1/4 NPT- M, |

| Angle valve with pressure relief device | ||

| 7 | Specifications | 50ml, 100ml, 150ml, 250ml, |

| 300ml, 500ml, 1000ml, | ||

| 2000ml, 2500ml, 4000ml, | ||

| 5000ml, 10000ml | ||

| 8 | Bottle Body | 1/4 NPT-F Feature - Double End Spinning Without Welding |

LPG Sampling Method

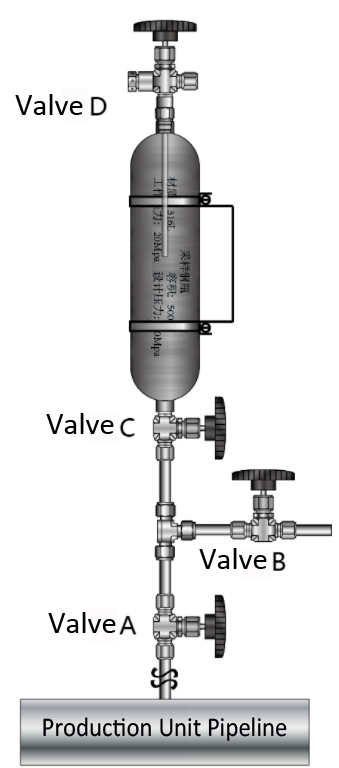

Our BPY G Liquefied  Petroleum Gas Sampling Cylinder are designed for easy and safe sampling in mainstream installations such as tanks, tankers, tower equipment, and production lines. Here’s a typical sampling method for LPG production pipelines:

Petroleum Gas Sampling Cylinder are designed for easy and safe sampling in mainstream installations such as tanks, tankers, tower equipment, and production lines. Here’s a typical sampling method for LPG production pipelines:

1. Select the Appropriate Liquefied Petroleum Gas Sampling Cylinder: Choose a Gas Sampling Cylinder with the required volume. For non-reserved volume tubes, weigh the Liquefied Petroleum Gas Sampling Cylinder before sampling.

2. Flush the Sampling Line: Connect the Gas Sampling Cylinder to the production unit using a metal hose, quick connector, and valve. Ensure all valves are closed before flushing the line with the sample.

3. Flush the Liquefied Petroleum Gas Sampling Cylinder: Place the Gas Sampling Cylinder upright with the outlet valve at the top. Open the control valve and fill the Gas Sampling Cylinder with liquid sample. Repeat this process at least three times to ensure cleanliness.

4. Sampling Process: Fill the Gas Sampling Cylinder with liquid samples, close the inlet valve, and relieve pressure through the discharge valve. Remove the Liquefied Petroleum Gas Sampling Cylinder and sampling line after pressure relief.

5. Adjust Sampling Quantity: For non-reserved volume tubes, weigh the LPG Sampling Cylinder

to determine the sample mass. For reserved volume tubes, discharge liquid until vapor appears, retaining 80% or less of the sample.

6. Leak Check: Immerse the LPG Sampling Cylinder in water to check for leaks. Discard the sample if any leakage is detected.

7. Sample Preservation: Store samples in a cool place until testing is complete. Protect the LPG Sampling Cylinder with a special frame or valve nut to prevent accidental opening or damage.

Optional Accessories

To enhance the functionality and adaptability of our LPG Sampling Cylinder ASTM D1265, we offer a range of optional accessories:

- PTFE Coating: Apply PTFE to the inner surface to prevent sample absorption and improve corrosion resistance.

- Metal Hose: Flexible and durable, suitable for connecting LPG Sampling Cylinder to various devices.

- Pressure Gauge: Monitor sample pressure in real-time to ensure safety.

- Quick Connector: Easy-to-use connectors for quick and secure connections.

- Reserved Volume Tube: Provides essential evaporation space to prevent pressure spikes.

- Reducer Pipe Joint: Facilitates connections between sampling equipment and production devices.

- LPG Sampling Cylinder Holder: Designed for safe and convenient storage and transportation of LPG Sampling Cylinder.

Why Choose Our BPY G Series LPG Sampling Cylinder ASTM D1265 ?

- Quality and Safety: Our LPG Sampling Cylinder ASTM D1265 are manufactured and tested according to international standards, ensuring reliability and safety in every application.

- Customization: With a wide range of accessories and configurations, our LPG Sampling Cylinder ASTM D1265 can be tailored to meet your specific sampling needs.

- Versatility: Suitable for a variety of industries and applications, our LPG Sampling Cylinder ASTM D1265 provide a versatile solution for all your sampling requirements.

- Durability: Made from high-quality 316L stainless steel, our LPG Sampling Cylinder ASTM D1265 are built to last, even in the most demanding environments.

Contact us today to learn more about our BPY G Seamless Sampling Cylinder ASTM D1265 and how they can enhance your sampling operations.