January 1, 2025 Contract Signed on New Year's Day

On January 1, 2025, Mr. Maher Saleh, representing a leading petroleum laboratory in Dubai, returned to the Dalian All World I/E Co., Ltd. (AWD) facility. After a final walk-through of the production line and a technical review with AWD General Manager Mr. Andy Diao, the customer placed his first purchase order for a complete lubricating-oil analysis instrument package, marking the very first order received by AWD in 2025.

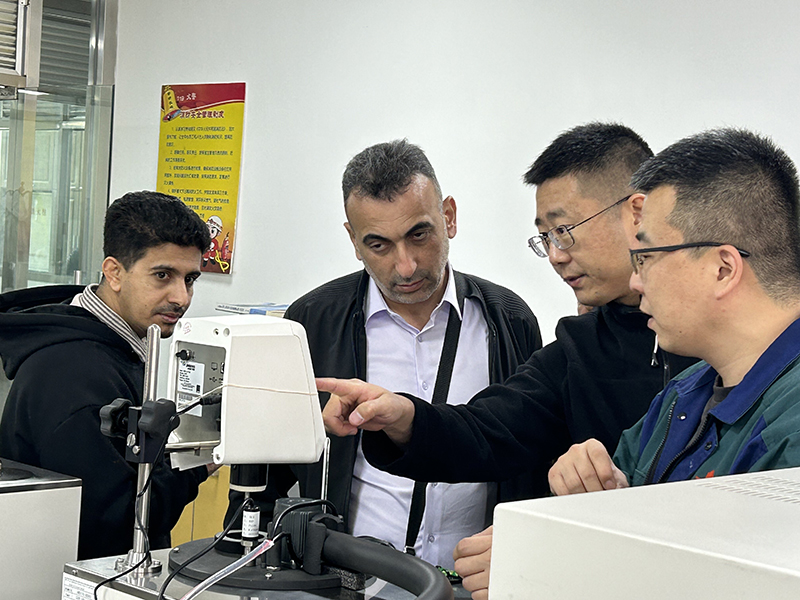

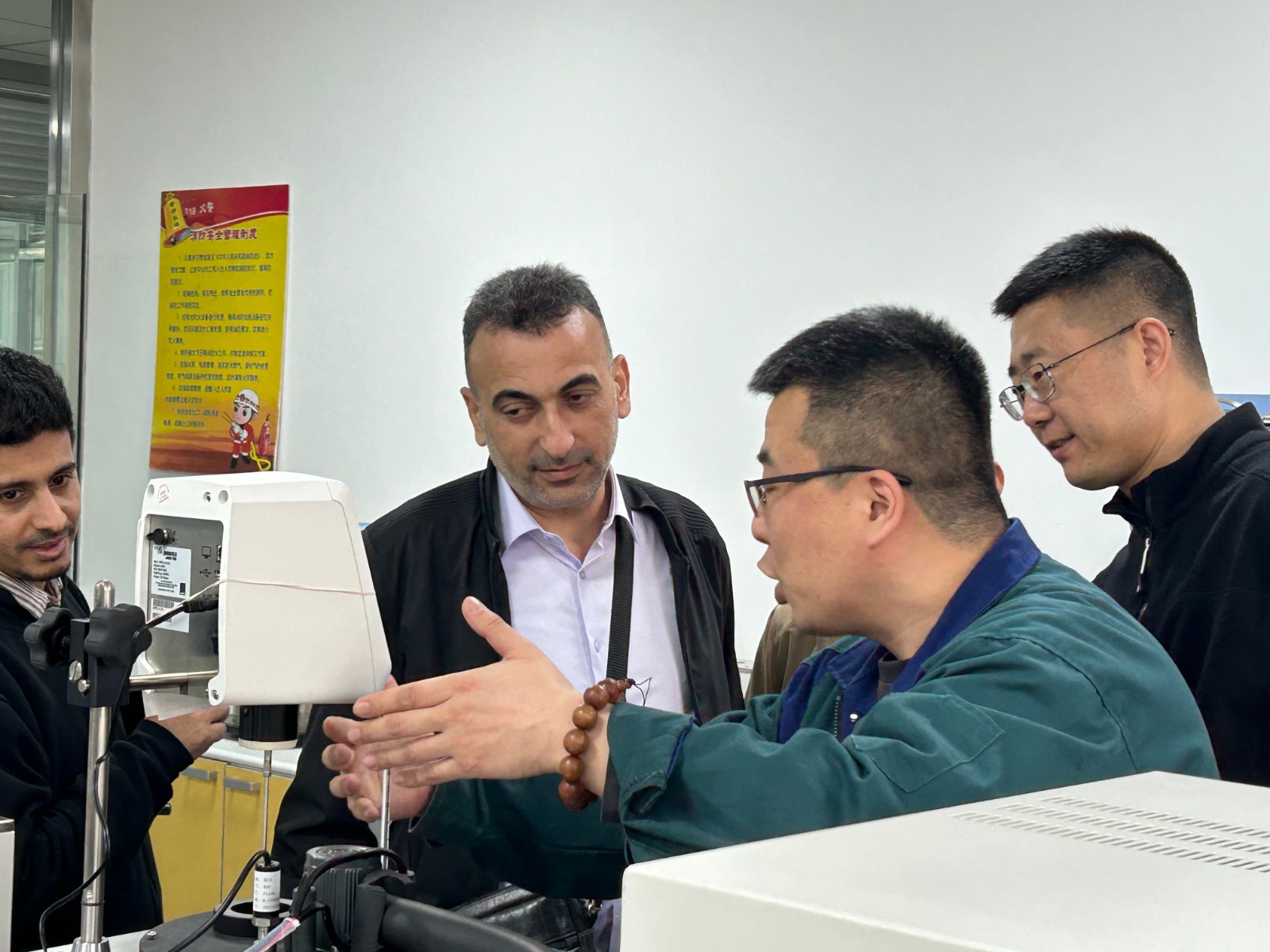

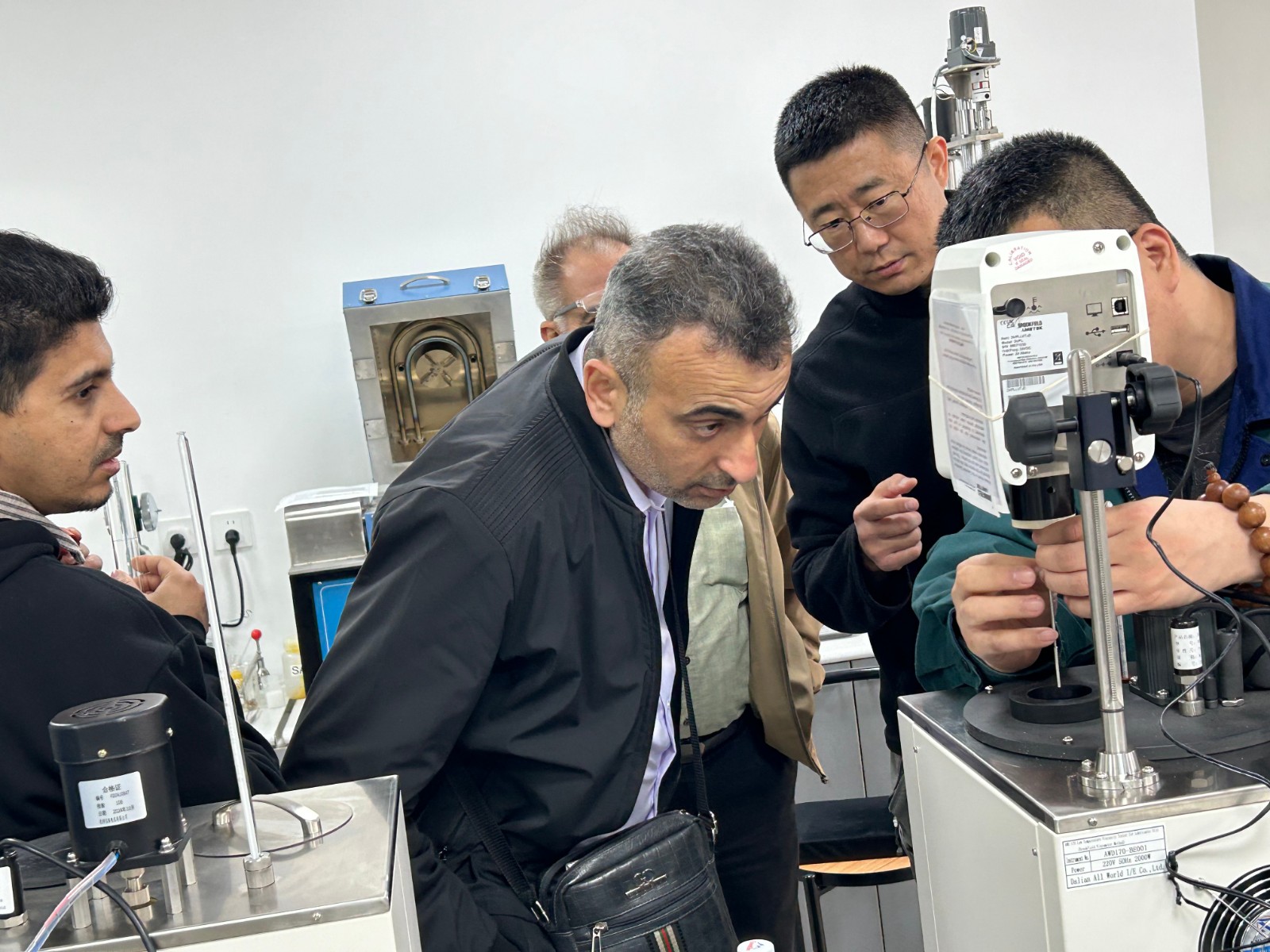

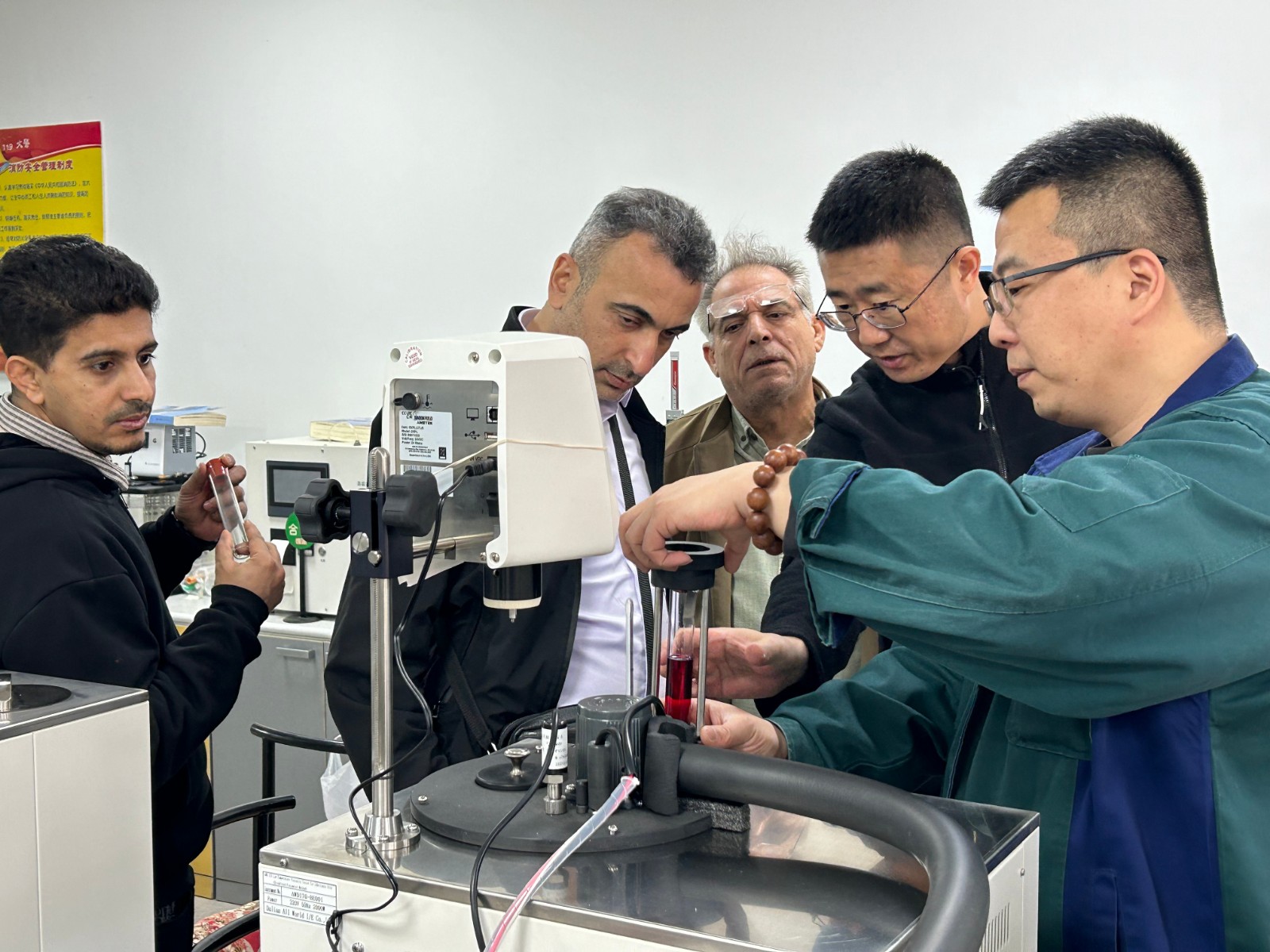

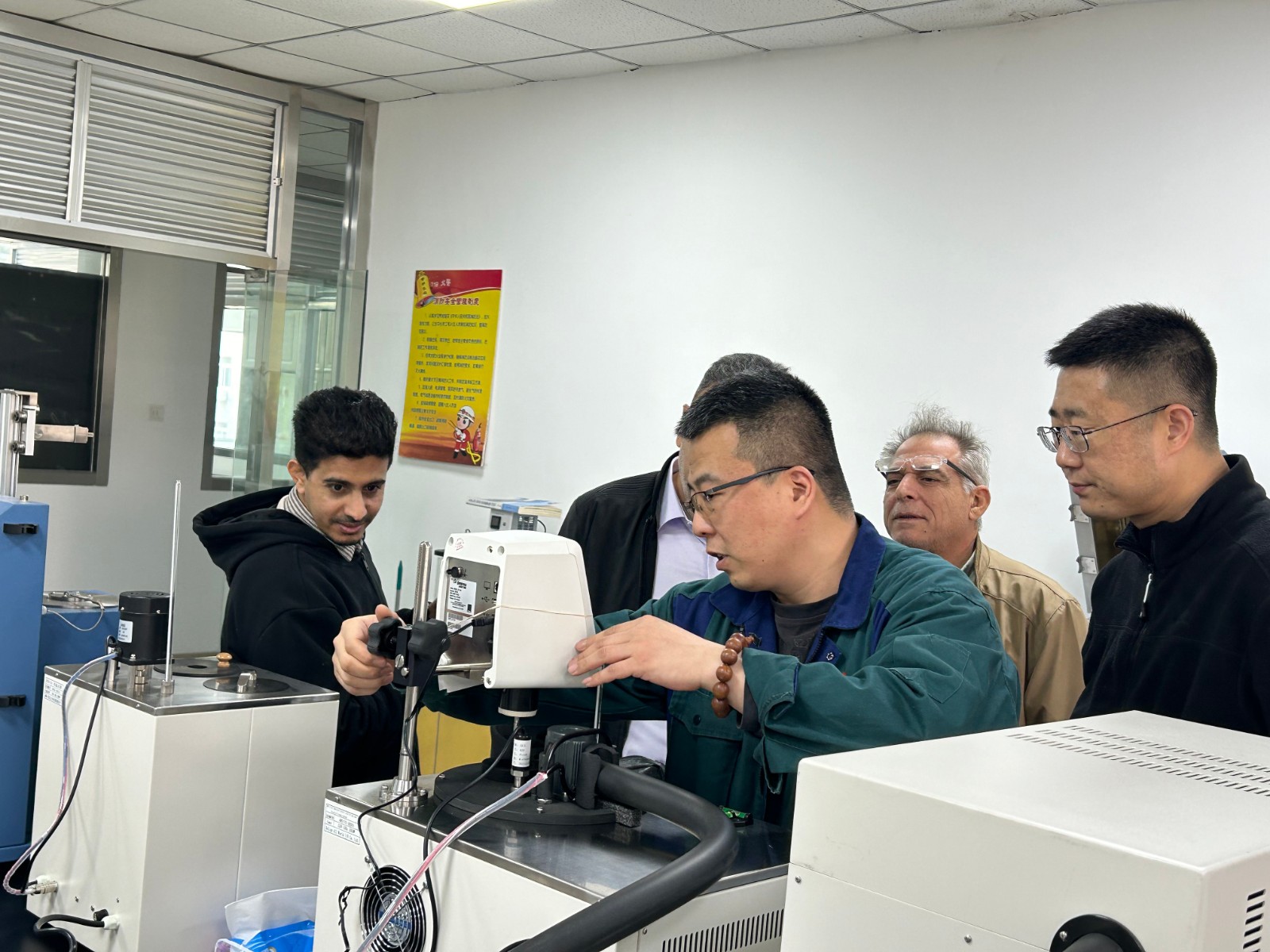

April 2, 2025 Pre-Shipment Inspection

April 2, 2025 – Mr. Saleh arrived in Dalian for the pre-shipment inspection. He brought his own reference samples and ran tests on the AWD-170 low-temperature viscosity tester, confirming that the results aligned with his laboratory’s historical data. All acceptance criteria were met; the customer signed the inspection certificate and authorized shipment to Dubai.

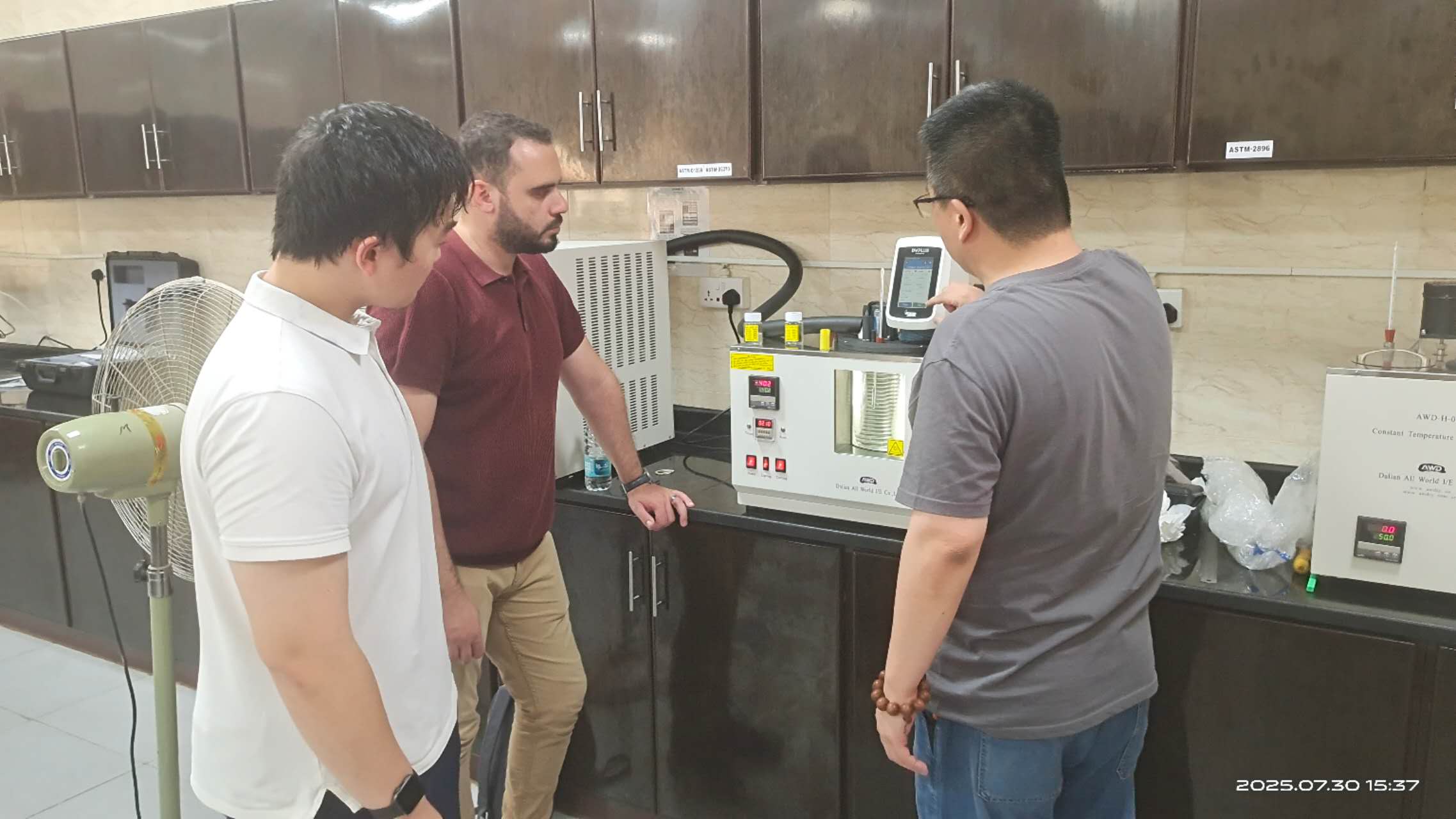

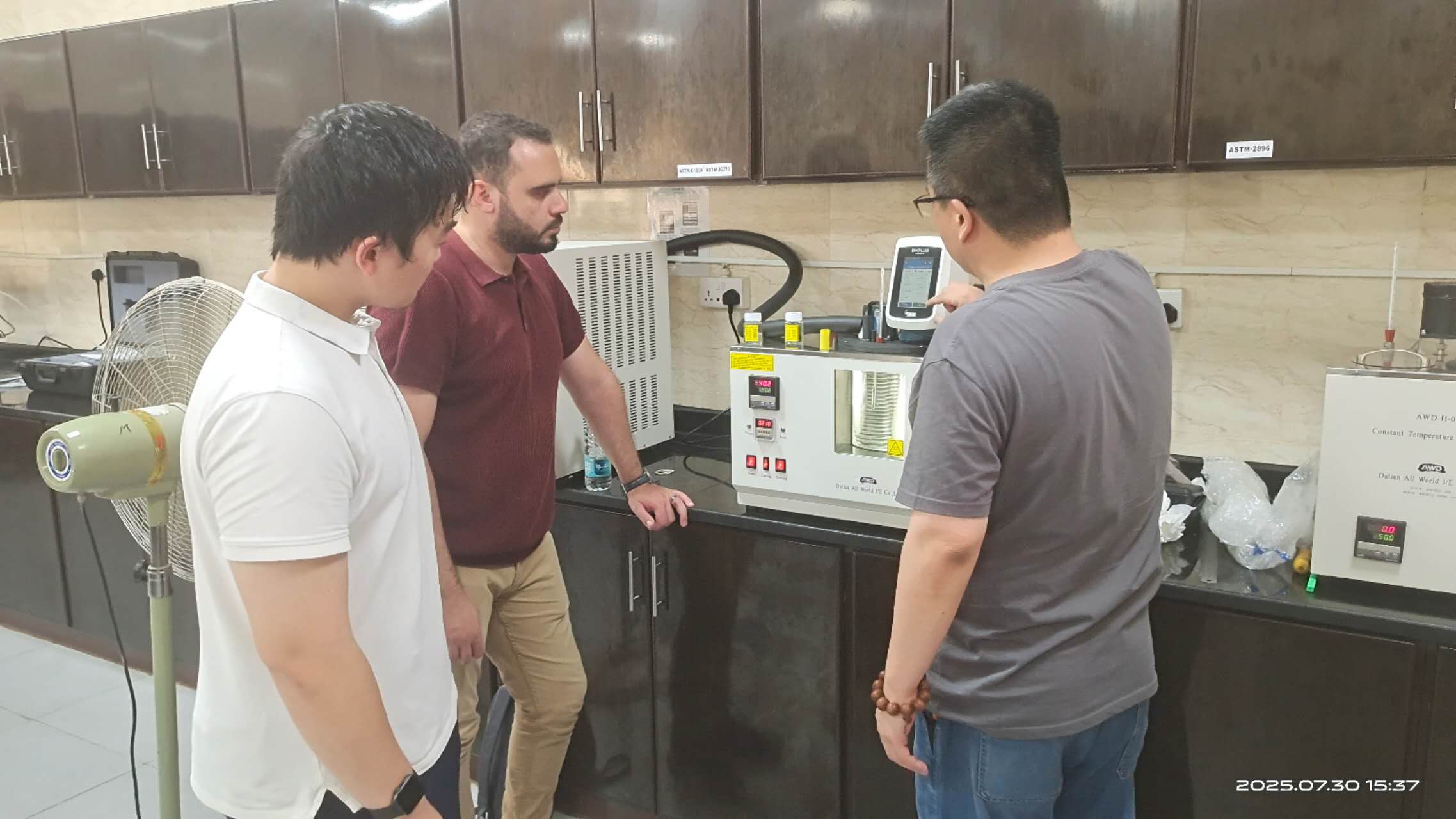

July 28, 2025 On-Site Installation, Commissioning, and Training

July 28, 2025 – The six-unit AWD lubricating-oil analysis equipment reached Dubai. From July 29 to August 3, AWD senior engineers completed mechanical installation, electrical hookup, and software calibration for:

• AWD-170 Low-Temperature Viscosity Tester

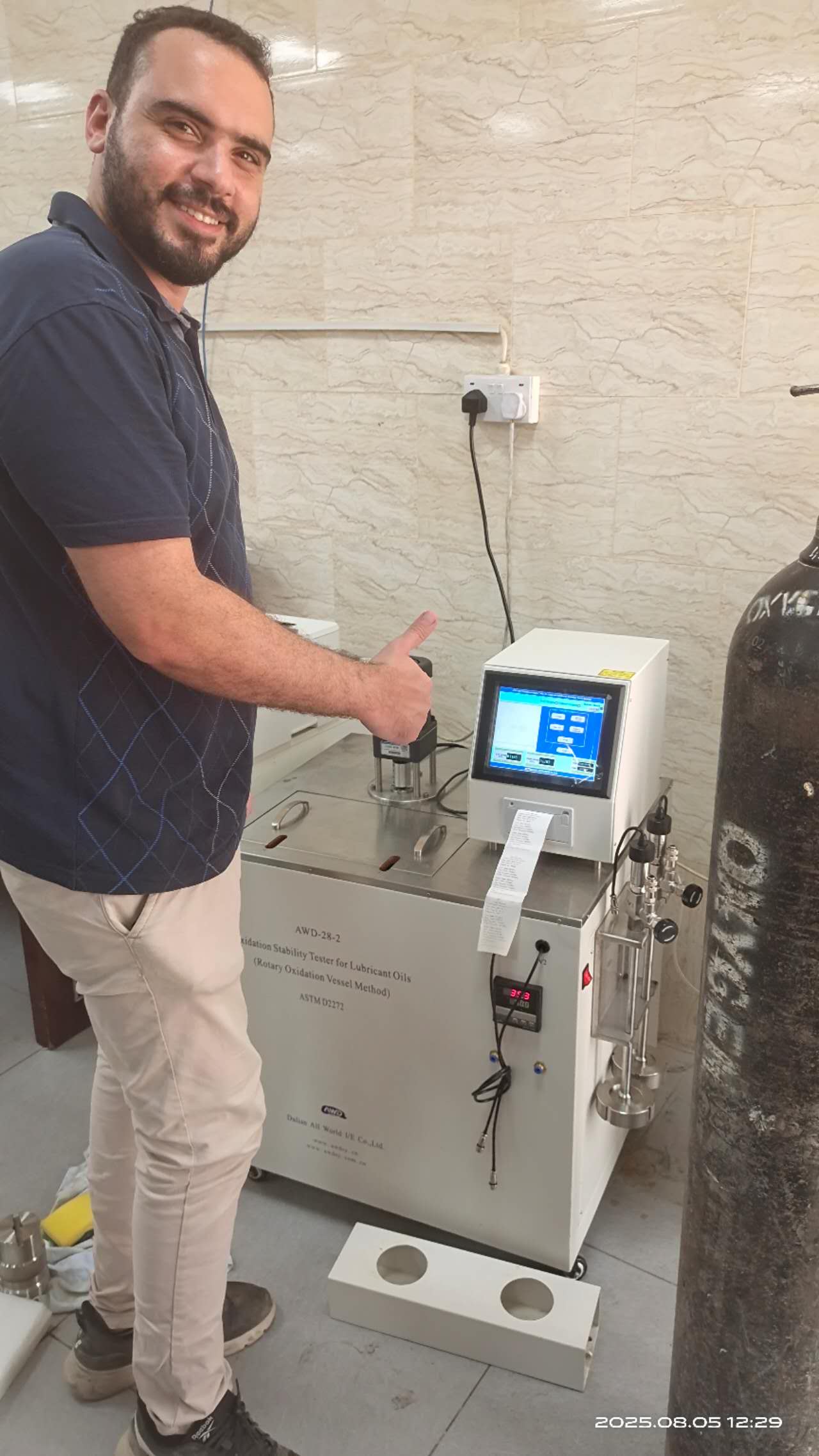

• AWD-28-2 Oxidation Stability Tester for Lubricant Oils

• AWD-311 Apparent Viscosity Tester

• AWD-31B Lubricating-Oil Evaporation-Loss Tester

• AWD-24B High-Temperature Foaming Characteristics Tester

• AWD-39 Carbon & Ash Content Tester

During the subsequent 48-hour training block, laboratory technicians practiced ASTM-compliant methods for low-temperature dynamic viscosity, oxidation stability, evaporation loss, anti-foam properties, and sulfated ash determination. The customer set very high requirements for the test results of the Lubricating Oil Analysis Equipment. In the laboratory, the customer used this newly installed Lubricating Oil Analysis Equipment to run repeated tests on multiple samples and compared the results with those from third-party laboratories. The facts proved that the low-temperature dynamic viscosity, oxidation stability, evaporation loss, anti-foam properties, and ash content obtained by these instruments were very accurate. The customer’s quality director gave a thumbs-up on the spot: “The accuracy and stability of this Lubricating Oil Analysis Equipment far exceed expectations!”

August 6, 2025 Follow-Up Cooperation Agreement

The customer’s CEO stated that within the next 12 months they will purchase additional units of the same series of Lubricating Oil Analysis Equipment and invited our company to serve as their technical service support partner in the Gulf region. This move not only consolidates our company’s leading position in the Lubricating Oil Analysis Equipment segment, but also adds another benchmark case for the globalization of China’s high-end testing instruments.